O RINGS

O-rings are one of the most common seals used in separate machine parts and components.They are designed to sit between two separate components in a groove to prevent leaking of fluids and gases.

O Rings are inexpensive, easy to make, reliable and have simple mounting requirements.They have been tested to seal up to 5000 psi of pressure. The maximum recommended pressure of an O-ring seal depends on the seal hardness and gland clearance.

O-rings are very commonly found in pumps, cylinders, pipe joints and connectors and valves in many Industries.The O Ring sits in the groove between two surfaces. Under compression the O Ring block any pathway between the two surfaces and prevent leaking of fluids and gases. O Rings are used to very effectively to seal static and dynamic applications.

Dura Metal offer a wide range of O Rings in terms of materials and sizes for the Mining and Oil and Gas Industries.In the Mining Industry, Pumps and Machines are operating in extremely abrasive conditions and the O Rings used from Dura Metal meets the highest standards.

In the Oil and Gas Industry, Dura Metal has been supplying Connector Casing O Rings, O Rings for Casing Thread Protectors and for Gas Drill Pipes,Besides standard O Rings, Dura Metal is able to custom make O Rings for specific application promptly and most competitively.We have O Rings for high temperature sealing, high pressure sealing, volatile gaseous sealing and abrasive media application.

Dura Metal O Rings comply to International Standards namely: ISO 3601, AS 568, JIS B2401( P,G and V Series)

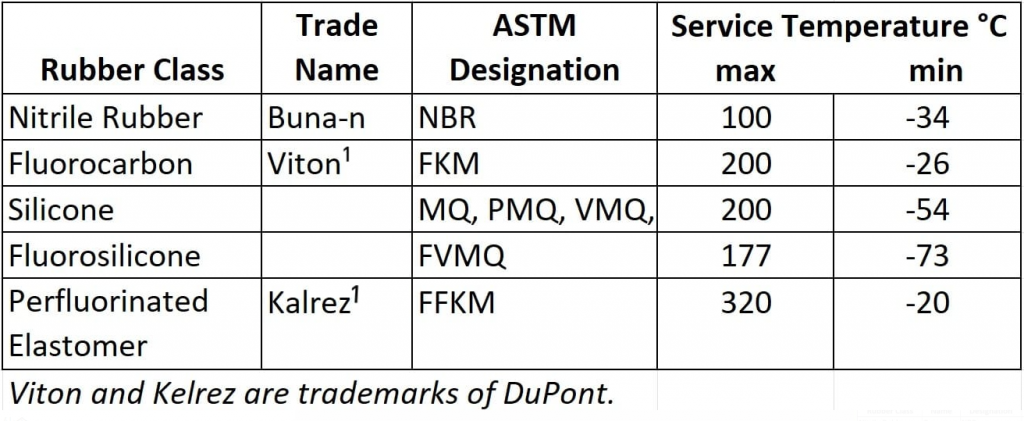

Material ranges from Natural Rubber, Synthetic Rubber Compounds like Fluorine, Silicon, Nitrile Butadiene, Butyl, Ethylene-Propylene, Chloroprene, etc. and Custom Compounds and Formulations.

(Select various aspect of O-Rings Tabulation, Pictures of Application, and for example material/temperature range below)

Material Temperature Range

OR